Concrete is the backbone of modern infrastructure. Whether it’s a towering skyscraper, a sturdy bridge, or a simple residential foundation, the quality of concrete determines the strength, durability, and longevity of any structure. One of the most critical processes in ensuring high-quality concrete is compaction—and High Frequency Vibrators are the go-to solution for achieving it effectively.

In this blog, we’ll explore what High Frequency Vibrators are, how they work, and why they’ve become indispensable in construction. We’ll also discuss the numerous benefits they offer, along with tips for selecting the right equipment from trusted High Frequency Vibrators Manufacturers and High Frequency Vibrators Suppliers.

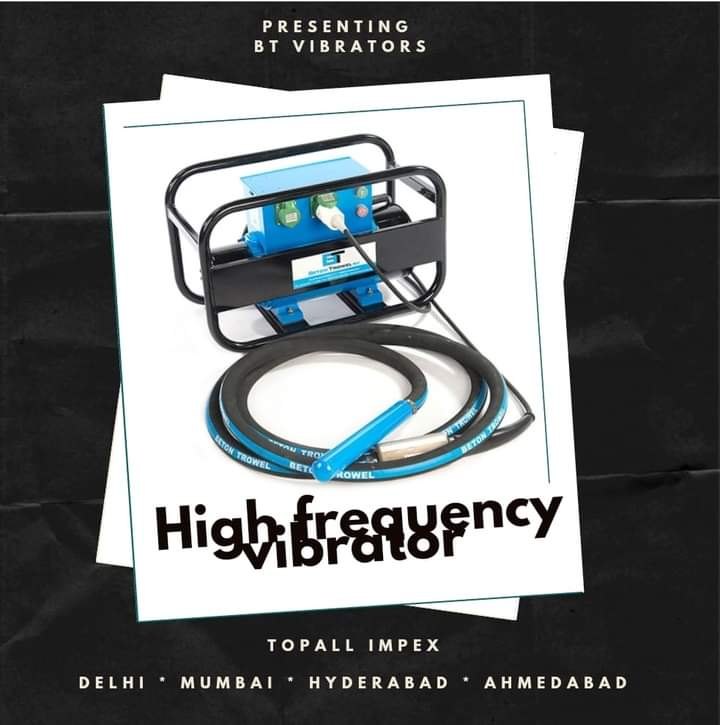

What Are High Frequency Vibrators?

High Frequency Vibrators are specialized tools designed to remove air bubbles and voids from freshly poured concrete. By vibrating at a higher frequency than conventional vibrators, they achieve quicker and more efficient compaction, ensuring that the concrete mixture settles evenly and bonds firmly.

Typically, these machines operate at frequencies above 10,000 vibrations per minute (vpm), which results in rapid particle rearrangement and a denser concrete structure.

They come in various forms:

- Internal (Immersion) Vibrators – inserted directly into the concrete.

- External Vibrators – attached to the formwork.

- Surface Vibrators – used for thin slabs and surfaces.

Why Concrete Compaction Matters

Proper compaction is not just a construction formality—it is a necessity. Without it, the structure will have:

- Air pockets and voids leading to reduced strength.

- Poor surface finish that can crack over time.

- Weak bonding between aggregates, making the concrete prone to wear and tear.

High Frequency Vibrators address these issues by delivering consistent, deep, and rapid vibrations, pushing out entrapped air and allowing the particles to settle tightly.

Key Benefits of Using High Frequency Vibrators in Concrete Compaction

1. Superior Concrete Strength and Durability

The primary benefit of using High Frequency Vibrators is the improved compressive strength of concrete. By eliminating voids and ensuring uniform density, the resulting structure can withstand higher loads and stress over its lifespan.

Why it matters:

A well-compacted concrete slab or column has fewer weak spots, which means fewer repairs and longer structural integrity.

2. Faster Compaction Process

Compared to traditional vibrators, High Frequency Vibrators work at higher speeds, significantly reducing the time needed for compaction. This allows construction teams to speed up project timelines without compromising quality.

Example:

A concrete column that may take 3–4 minutes with a standard vibrator can be compacted in under a minute with a high-frequency model.

3. Better Surface Finish

High frequency vibrations cause the cement slurry to rise to the surface, producing a smoother, more uniform finish. This is particularly beneficial for visible structures like exposed concrete walls, architectural facades, and decorative slabs.

4. Reduced Honeycombing and Voids

Honeycombing refers to gaps or holes on the concrete surface caused by poor compaction. High Frequency Vibrators prevent this by ensuring every corner of the formwork is filled and compacted.

5. Increased Structural Lifespan

Dense, void-free concrete is less permeable, meaning water and chemicals have a harder time penetrating. This reduces corrosion of reinforcement bars and increases the structure’s lifespan.

6. Versatility Across Applications

From high-rise buildings to bridges, tunnels, dams, and precast concrete products, High Frequency Vibrators are suitable for almost every type of concrete work. They’re also available in portable and fixed configurations to suit different job sites.

7. Reduced Labor Costs

Faster compaction means less manpower and time spent on each pour. This efficiency directly translates into cost savings for construction companies, especially on large-scale projects.

8. Consistent Quality Across Projects

Whether you’re working on a small residential project or a massive infrastructure development, using High Frequency Vibrators ensures consistent results every time. Uniform compaction means predictable performance and fewer defects.

Choosing the Right High Frequency Vibrator

When selecting a High Frequency Vibrator, consider the following factors:

- Frequency and Amplitude – Choose a model that provides the right vibration intensity for your concrete mix.

- Durability – Look for rugged construction, as these machines often work in challenging environments.

- Power Source – Options include electric, pneumatic, or petrol-driven vibrators depending on site conditions.

- Portability – For large sites, lightweight and mobile units are easier to maneuver.

- Brand Reputation – Opt for trusted High Frequency Vibrators Manufacturers who follow strict quality control standards.

Maintenance Tips for Long-Term Performance

To get the best results and longest service life from your equipment, follow these practices:

- Clean after every use to prevent concrete residue buildup.

- Check cables and connectors regularly for wear.

- Lubricate moving parts according to the manufacturer’s instructions.

- Inspect the motor for overheating or unusual sounds.

- Store properly in a dry, sheltered location.

Working with Reliable Suppliers and Manufacturers

Investing in high-quality equipment starts with choosing the right High Frequency Vibrators Manufacturers and High Frequency Vibrators Suppliers. Partnering with reputable companies ensures:

- Access to advanced models with better efficiency.

- Availability of genuine spare parts.

- After-sales service and technical support.

- Compliance with safety and quality standards.

Conclusion

High Frequency Vibrators are more than just tools—they’re an investment in quality, efficiency, and durability for any concrete project. From boosting strength and longevity to reducing labor costs and ensuring a flawless finish, the benefits they bring to concrete compaction are undeniable.

By sourcing from trusted High Frequency Vibrators Manufacturers and working with reliable High Frequency Vibrators Suppliers, construction professionals can ensure they’re getting the best equipment for the job. In today’s fast-paced construction industry, where time and quality are equally important, high-frequency technology is not just an advantage—it’s a necessity.