In the ever-evolving world of custom apparel, shirt printing remains one of the most in-demand and creative outlets for personal expression, branding, and fashion. Whether for small businesses, sports teams, or personal wear, printed shirts can make a bold statement. With advancements in technology, there are now multiple methods available to print on shirts—each with unique qualities, advantages, and best-use cases.

In this article, we’ll explore the most popular types of shirt printing methods, their pros and cons, and which ones are best suited for your printing needs.

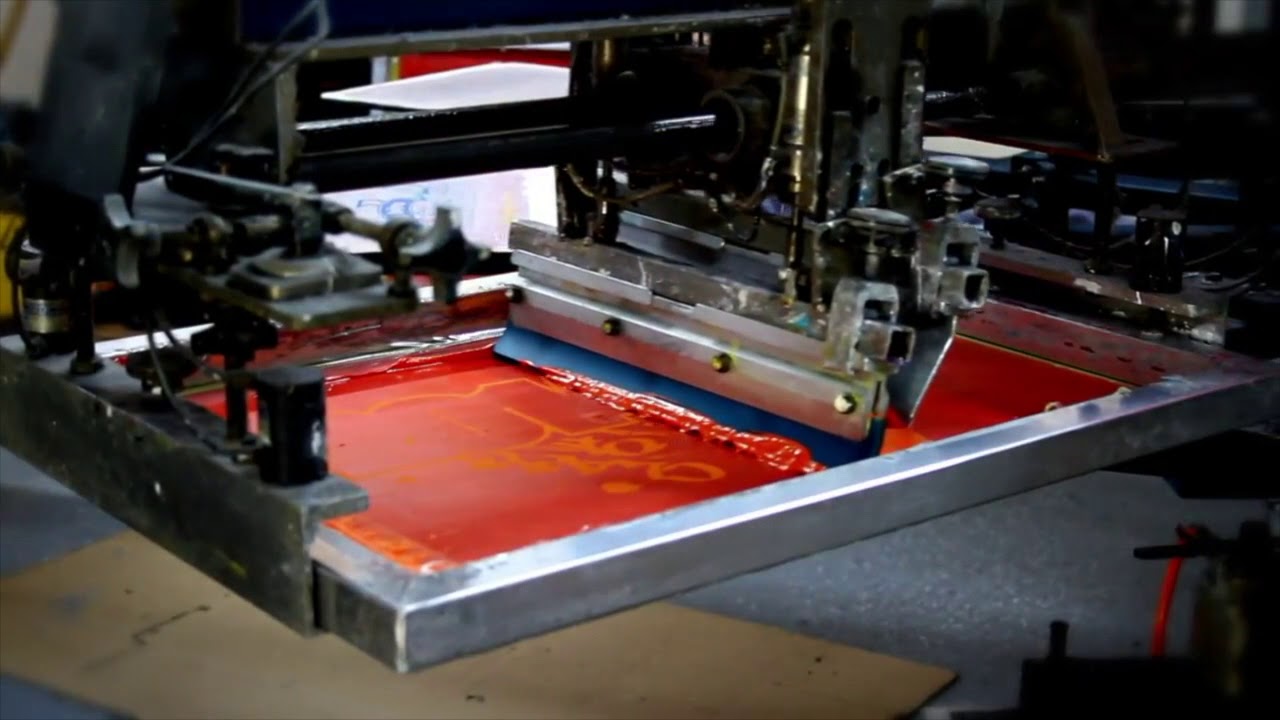

1. Screen Printing

Overview:

Screen printing, also known as silkscreen printing, is one of the oldest and most popular methods. It involves creating a stencil (or “screen”) and using it to apply layers of ink onto the shirt fabric.

Best For:

Large quantities of the same design, especially simple, bold designs with few colors.

Pros:

- Durable and long-lasting prints

- Vibrant colors

- Cost-effective for bulk orders

Cons:

- Not ideal for highly detailed or multi-color designs

- Expensive setup for small runs

2. Direct-to-Garment (DTG) Printing

Overview:

DTG printing works like an inkjet printer but for garments. The printer sprays water-based ink directly onto the fabric, allowing for highly detailed and colorful designs.

Best For:

Small batches, full-color artwork, and complex images like photographs.

Pros:

- No minimum order quantity

- Excellent detail and color gradients

- Eco-friendly water-based inks

Cons:

- Slower for bulk production

- Works best on 100% cotton shirts

- Colors may fade faster than screen prints

3. Heat Transfer Printing

Overview:

This method involves printing a design onto a special transfer paper and then using heat and pressure to transfer the design onto the shirt.

Subtypes include:

- Plastisol transfers

- Inkjet or laser transfer

- Dye-sublimation (covered separately below)

Best For:

On-demand printing, small orders, and one-off designs.

Pros:

- Great for full-color images

- Easy for small-scale or home production

- Can work on various fabrics

Cons:

- May crack or peel over time

- Not as breathable as other methods

- Not as durable after multiple washes

4. Dye Sublimation Printing

Overview:

This method uses heat to transfer dye directly into the fabric fibers. It’s mostly used for polyester fabrics and results in a soft, vibrant print that doesn’t fade, crack, or peel.

Best For:

All-over prints, sportswear, and polyester-based garments.

Pros:

- No feel on the shirt—the dye becomes part of the fabric

- Long-lasting and fade-resistant

- Perfect for complex and colorful designs

Cons:

- Only works on light-colored, polyester garments

- Not suitable for cotton shirts

5. Vinyl Heat Transfer (HTV)

Overview:

In this method, a machine cuts out designs from colored vinyl sheets, which are then heat-pressed onto the shirt. It’s commonly used for names, numbers, and slogans.

Best For:

Sports uniforms, personalized shirts, and simple graphics.

Pros:

- Durable and flexible print

- Vibrant, solid colors

- Great for small runs and personalization

Cons:

- Not ideal for intricate designs

- Can feel heavy on fabric

- Limited color and layering options

6. Embroidery (Bonus Option)

Overview:

While not technically a printing method, embroidery involves stitching a design directly onto the fabric using a machine.

Best For:

Logos, corporate shirts, polo shirts, and thicker fabrics.

Pros:

- High-end, professional look

- Extremely durable

- Doesn’t fade or peel

Cons:

- Not suitable for detailed or photographic designs

- More expensive

- Can feel rough on thin fabrics

Choosing the Right Shirt Printing Method

When selecting a shirt printing method, consider the following factors:

- Quantity: Screen printing is great for large orders; DTG or vinyl is better for small runs.

- Design Complexity: DTG and sublimation excel at detailed and colorful designs.

- Fabric Type: Sublimation works best on polyester, while DTG prefers cotton.

- Budget: Heat transfer and vinyl are cost-effective for limited runs; screen printing saves money in bulk.

- Durability: Embroidery and screen printing offer the longest lifespan.

Final Thoughts

With so many types of shirt printing available, there’s a perfect solution for every need—whether you’re launching a clothing brand, customizing team uniforms, or printing a one-time gift. Each method has its strengths, and understanding the differences helps you make informed choices for quality, durability, and cost-effectiveness.

Whether you’re printing in bulk or just creating a few custom tees, selecting the right printing technique ensures your designs come to life exactly as you imagined.

Ask ChatGPTTools